About a week ago I quit my job. I was a gallery attendant and spent most of my days sitting/standing + doing nothing + dreaming of what I could be doing. So I quit! Now I am currently working on some different projects

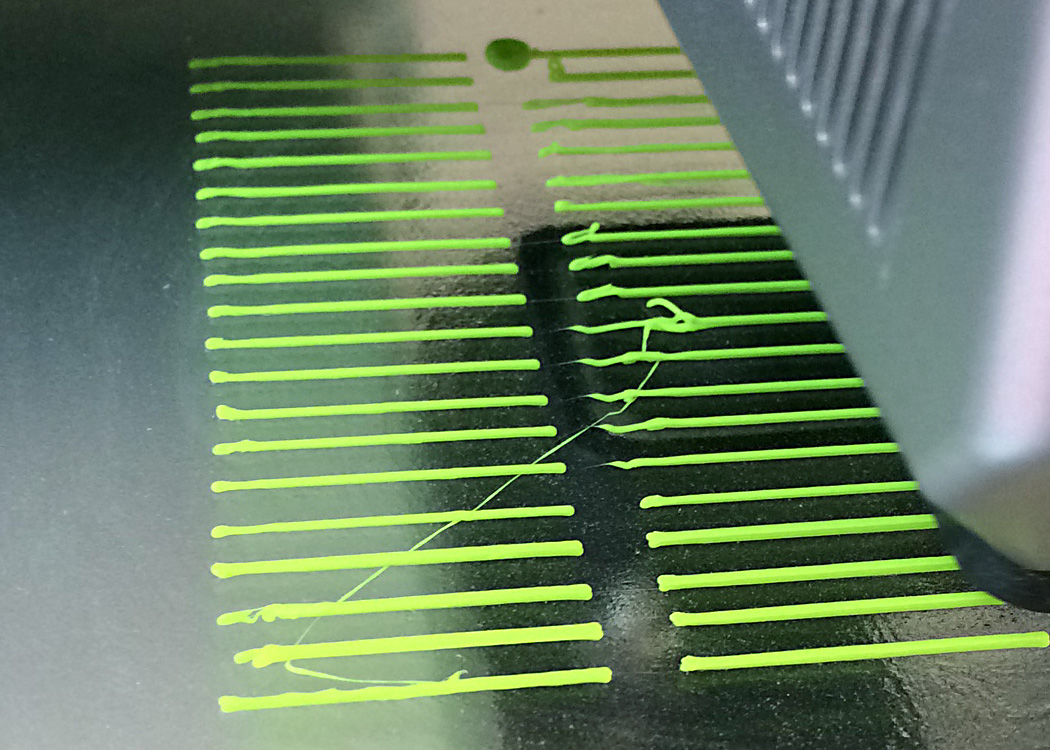

I have started doing some work with my father, Charles Sperry. He is an inventor/innovator living in Massachusetts. I have started doing some consulting work, as in I research and think about different products, designs, inventions and we create a dialogue. It's the type of work that I would really enjoy making a full time deal.

This website! What is it? We shall see.